Overview

We were prompted to create an injection molded toy based on the ideas and drawings of a class of 5th graders.

Context

Mechanical Engineering CapstoneSkills

Inspiration

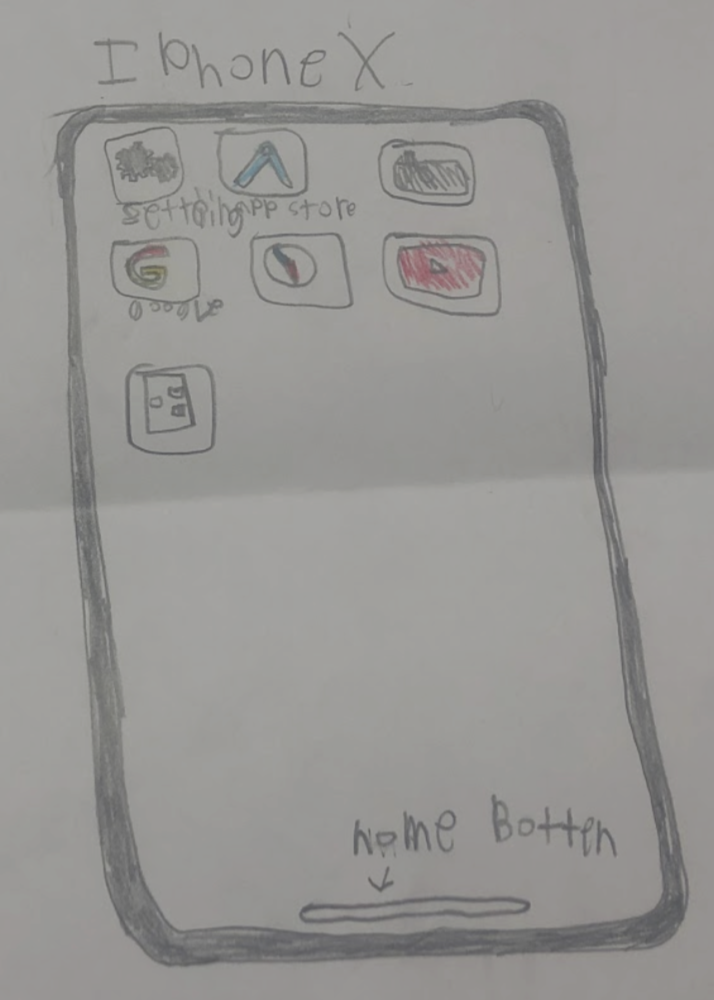

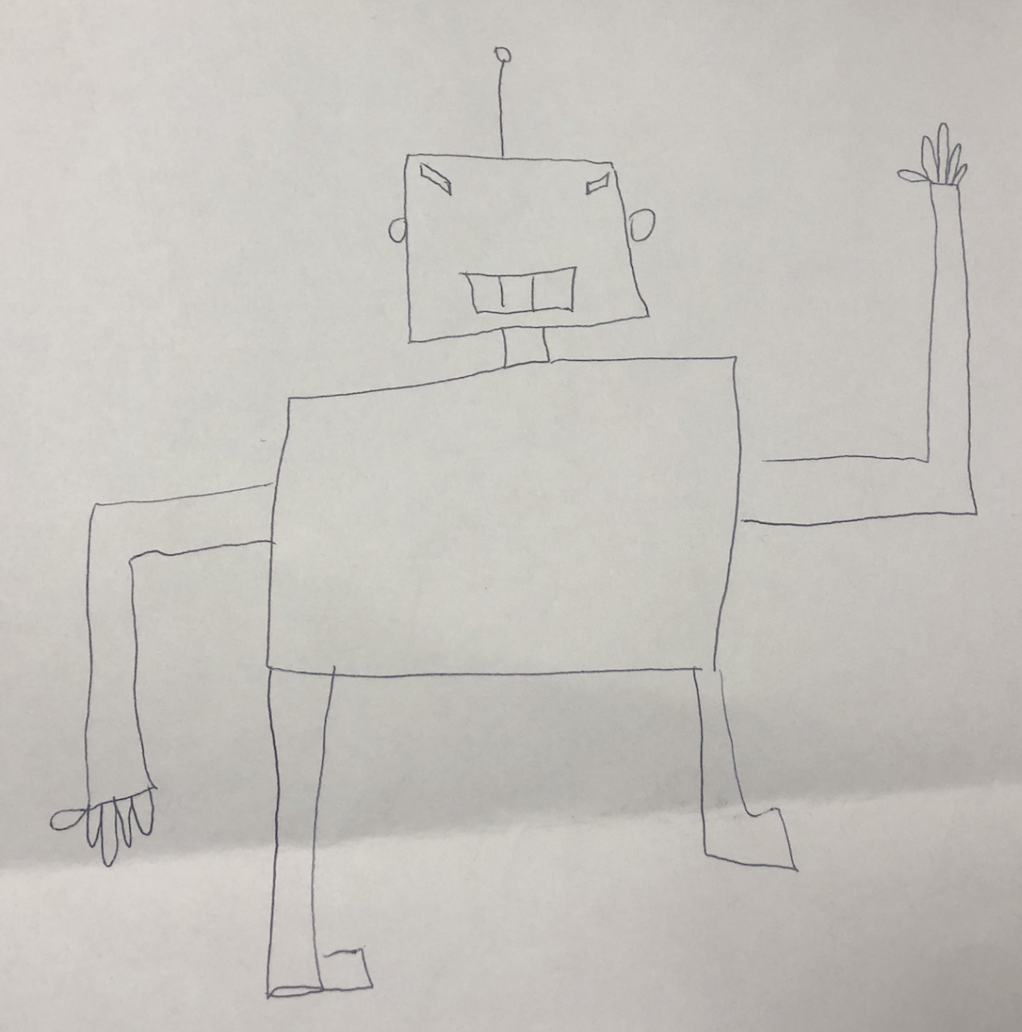

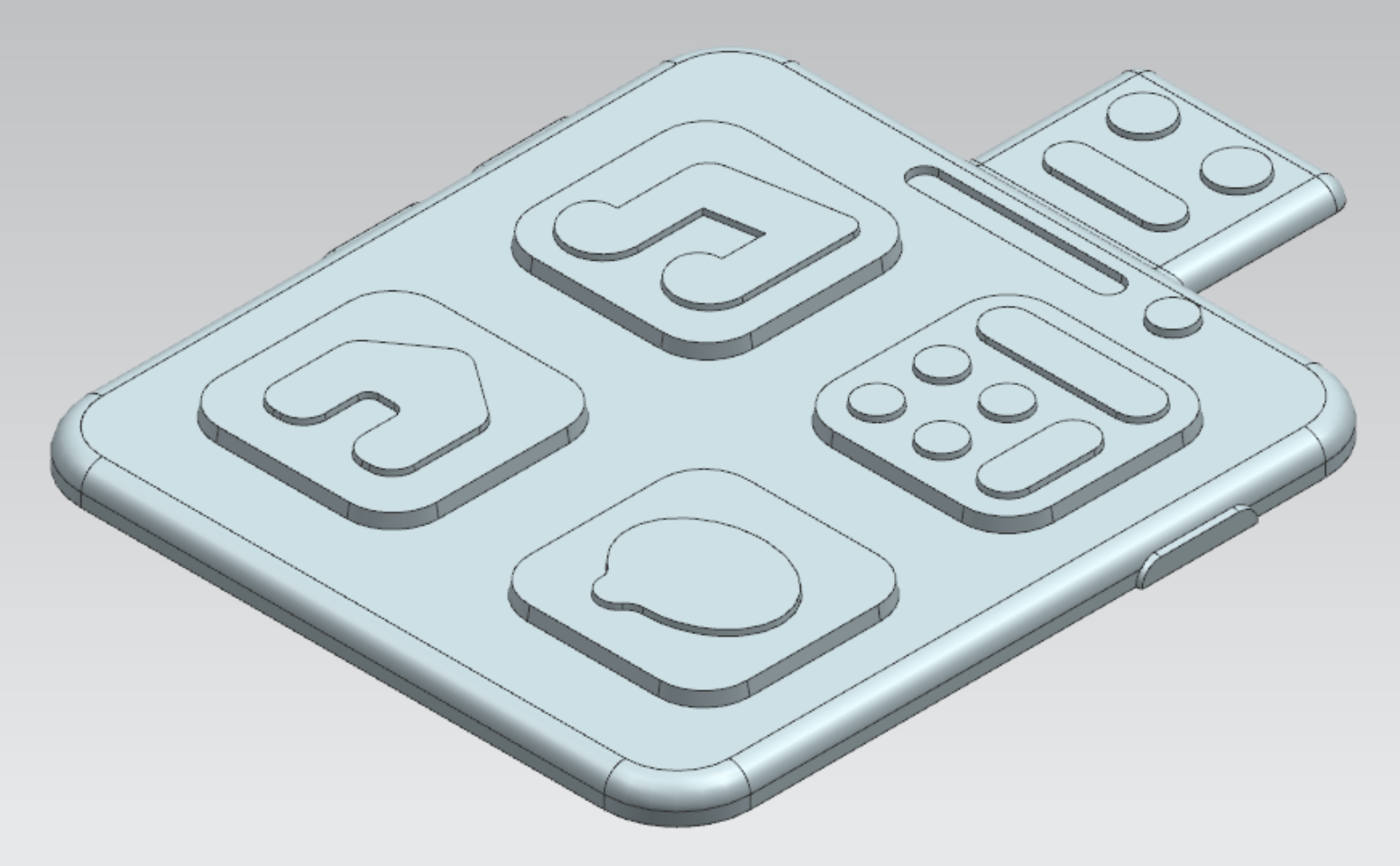

After careful evaluation of all the options, we chose a young artist, Johnny, to inspire our

product. Below are his illustrations.

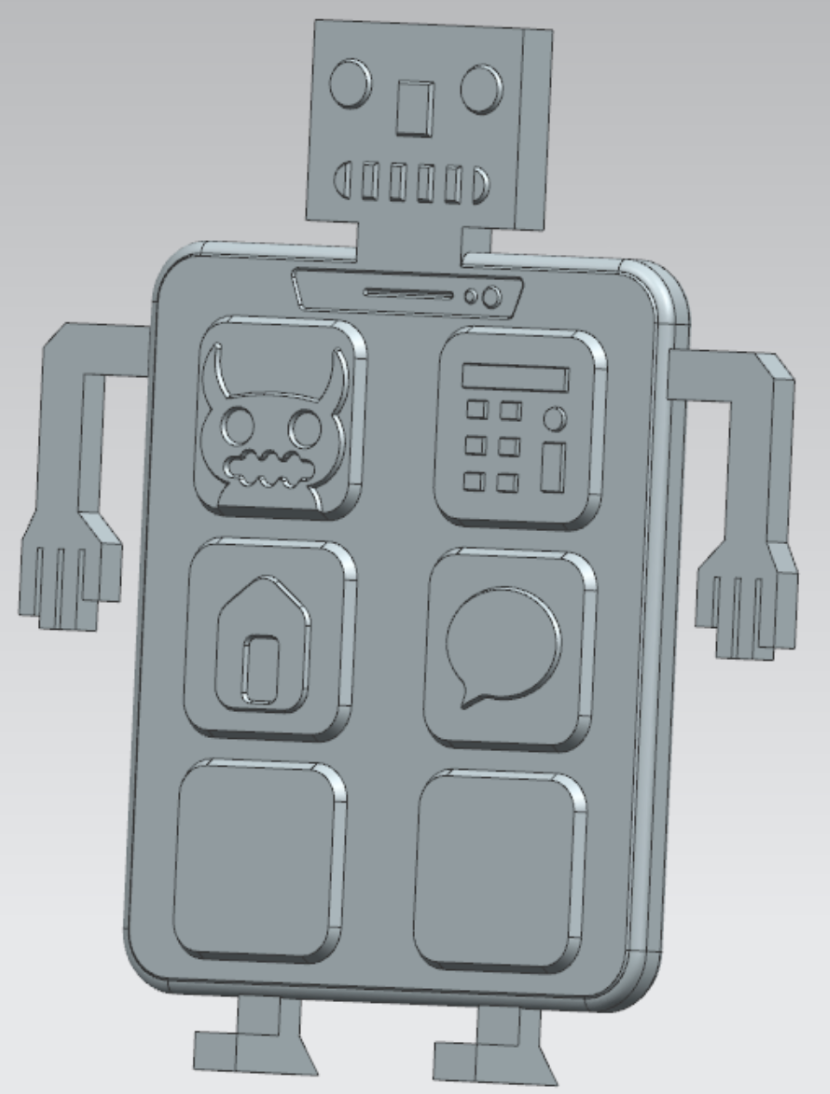

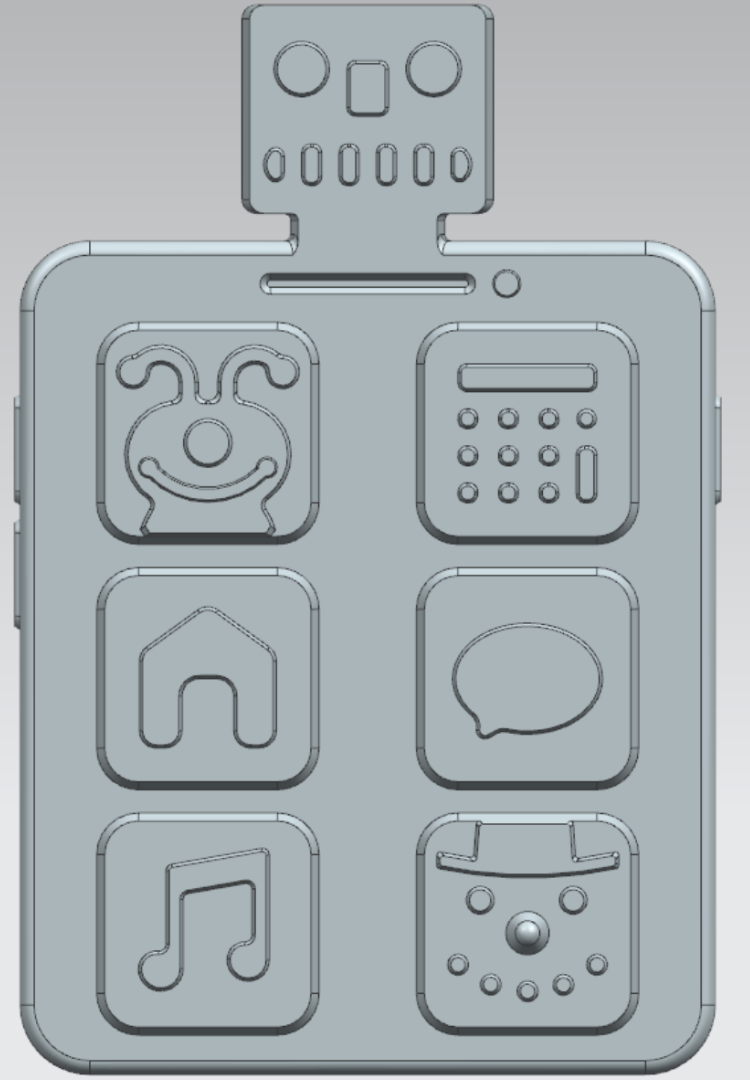

Design Phase

Part Design

First Iteration Issues

- The thickness variety across the product would require very calculated runner placement.b

- The sharp angles and small corners in the app designs would cause difficult machiening.

Second Iteration Issues

- Based on the tools in our machine shop there were a number of details for our app designs that would not allow for efficient machining.

- The neck connecting the body and the head could create risk in uneven plastic hardening during injection molding.

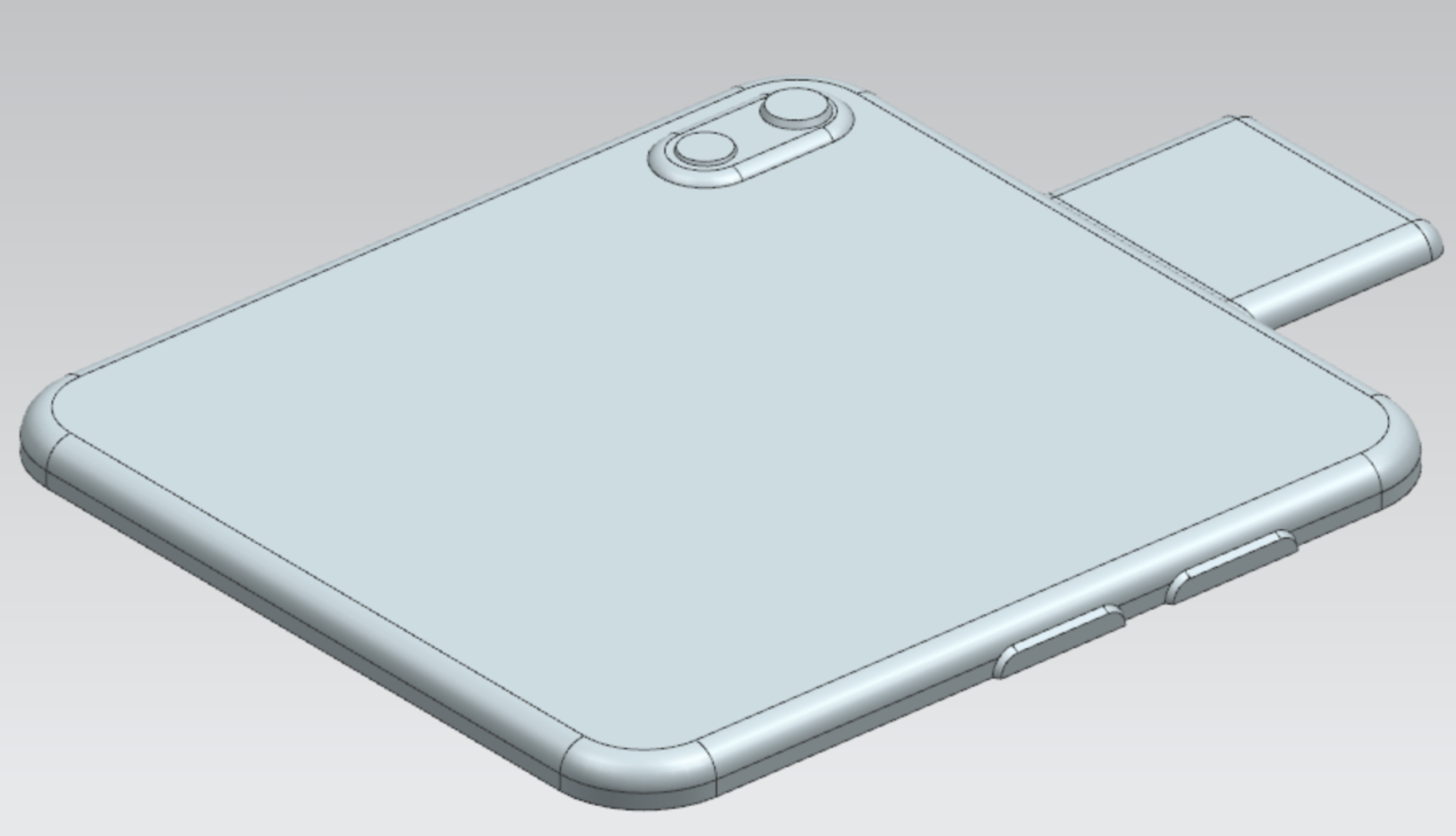

Final Design

Manufacturing Phase

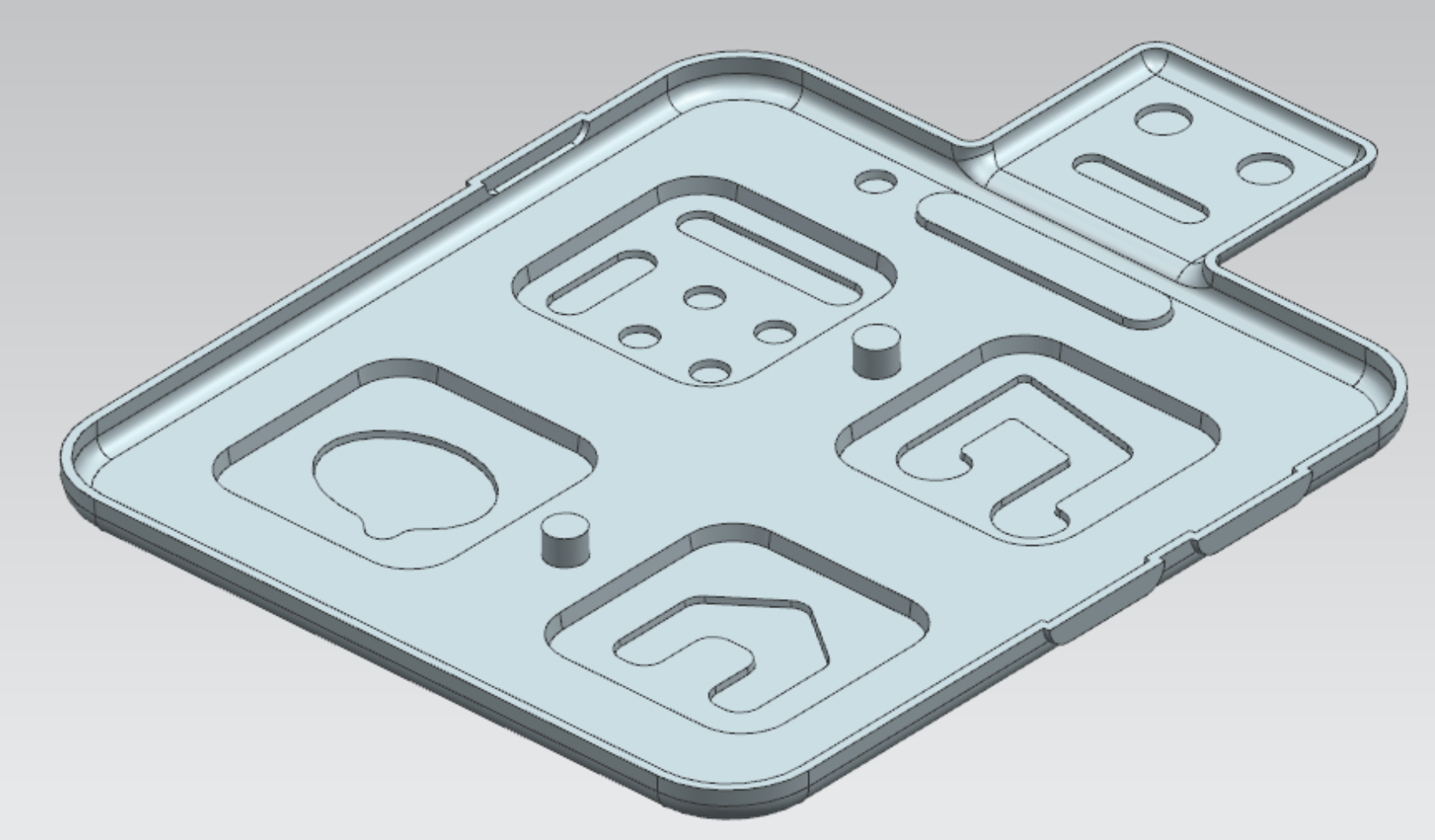

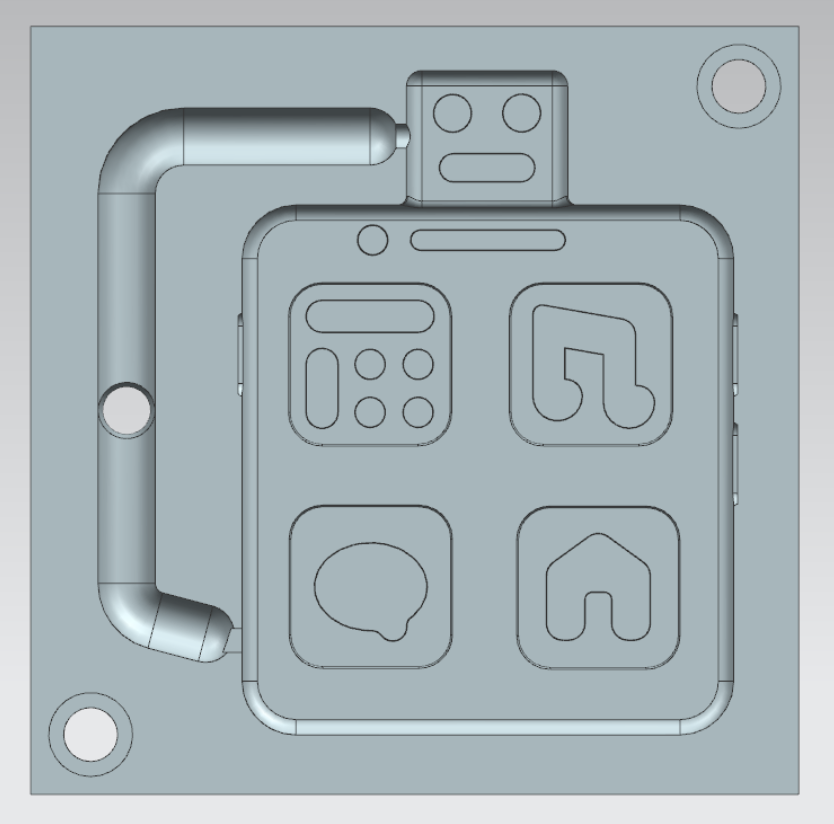

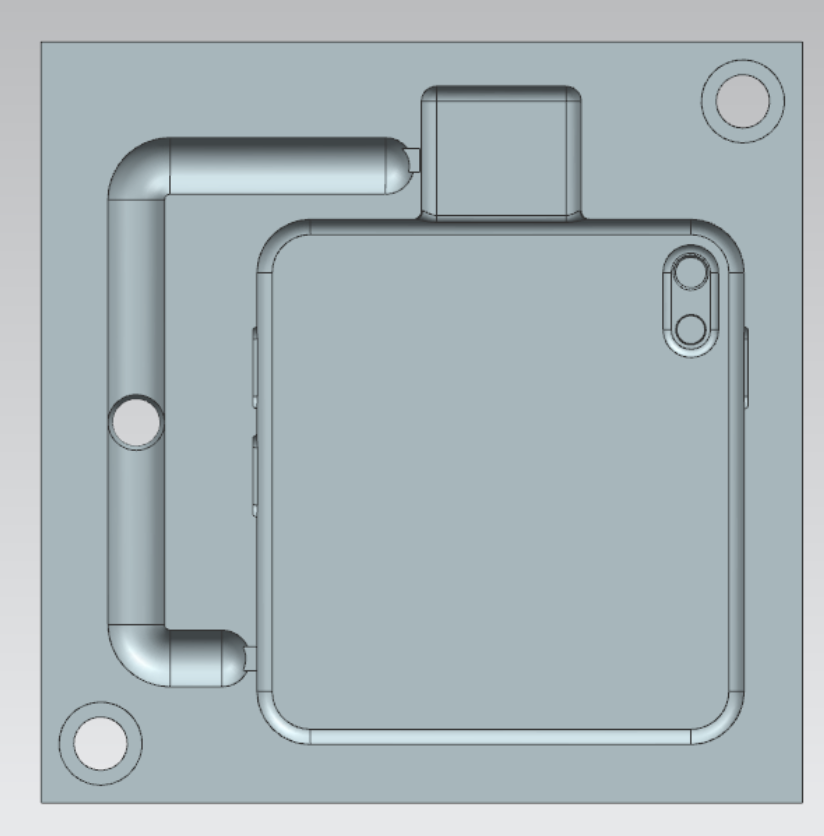

Mold Design

Attempted Interference Fits

- 4 corners of the iPhone

- Center of robot's face

- Runner design to ensure a clean injection molding process.

- Designing the gate thickness to ensure no short shot during the injection process.

Important Considerations to the Mold Design

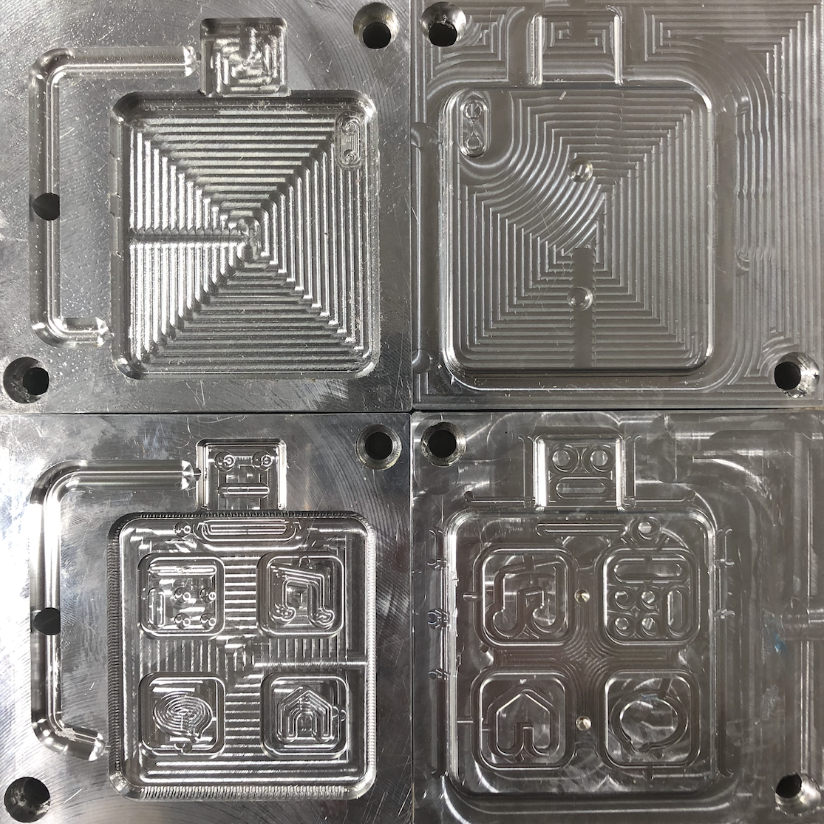

We then CNCed the mold for over 10 hours

Injection Molding

During the injection molidng phase we went through many iterations to best identify what combination of pressure and temperature would be most successful for our toy design.

Next steps...

- Increase wall thickness

- Change gate placement to avoid weld lines

- Change interference fit locations to create a flush alignment

- Decrease base plate temperature to reduce warping